Fashion brands constantly race against the clock to stay creative and deliver on time. Every stage between idea and final delivery plays a critical role. With increased demand for speed, precision, and innovation, many companies are turning to smarter solutions. Start transforming your product development process now with tools designed to improve every stage of your workflow.

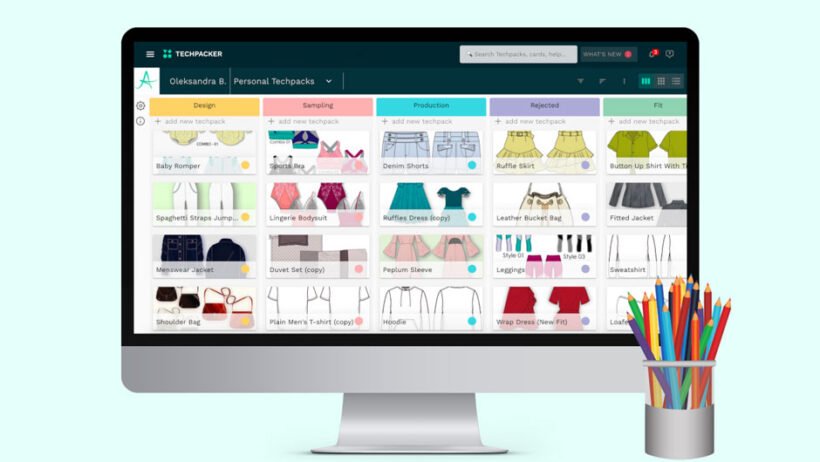

Within the first few months of use, many teams experience noticeable improvements by adopting fashion PLM software. It brings structure to the chaos of design, development, and production, allowing teams to work together more smoothly and efficiently. This article explores how it helps streamline collaboration and speed up development.

Improved Collaboration Across Departments

Departments that once worked in silos can now connect through a single platform. PLM software offers a centralized hub where design, merchandising, sourcing, and production teams share updates in real-time. This eliminates the delays and confusion that often arise from scattered communication tools.

Everyone can view the latest sketches, tech packs, or material specs without waiting on email threads or version updates. It becomes easier to assign tasks, track progress, and close feedback loops quickly. When collaboration improves, teams make faster, more confident decisions.

Faster Time to Market

Speed has become a key advantage in the fashion industry. PLM systems help compress development timelines by automating repetitive steps and streamlining design workflows. Features like integrated CAD tools and prebuilt templates cut down manual effort.

If a design change happens late in the process, the system updates everything connected to that style. There is no need to edit multiple spreadsheets or reissue tech packs. These updates flow through instantly, so teams can respond quickly and meet delivery deadlines with less stress.

Increased Accuracy in Product Data

One of the biggest sources of cost in fashion production comes from errors. Incorrect measurements, outdated specs, or missing information can lead to wasted samples or manufacturing issues. PLM software reduces these mistakes by organizing all product data in one place.

Every style has a single source of truth. Features like digital version control, BOM management, and standardized tech packs ensure consistency across every team and vendor. When the data is clean and organized, production runs more smoothly, and fewer costly errors occur.

Better Visibility into the Supply Chain

The software provides clear, real-time insight into every step of the product lifecycle. Managers can view the current status of styles, check material availability, monitor vendor timelines, and track budgets. This visibility makes it easier to make decisions based on facts, not guesswork.

Many systems connect with ERP and supply chain platforms, giving teams even broader access to operational data. Brands that see the full picture can spot issues early and adjust before delays or overages happen. Better visibility leads to better control.

Sustainability and Material Management

Fashion companies are under pressure to improve sustainability practices. The software helps by tracking material use, sourcing certifications, and supplier performance in one system. With built-in sustainability features, brands can:

- Reduce material waste through accurate forecasting.

- Compare vendors by environmental standards.

- Track recycled or eco-certified fabric usage.

- Minimize overproduction by analyzing past data.

- Plan collections with sustainability in mind.

These tools support responsible design without sacrificing speed or creativity.

Fashion PLM software is more than just a digital workspace. It helps fashion businesses work smarter, move faster, and reduce costly mistakes across the entire product journey. Integrating the PLM software into your workflow can be the change your team needs to thrive in a highly competitive market. Now is the time to take the next step forward.