The world of architectural woodworking and design is undergoing a dramatic transformation. From AI-assisted drafting to sustainable materials and hyper-personalized interiors, the future of custom design in 2026 is more digital, collaborative, and efficient than ever before.

Businesses, architects, and interior designers are reimagining what it means to create “custom” spaces blending craftsmanship with computational design to achieve precision, creativity, and scalability. With the growing role of architectural millwork drafting services and the widespread adoption of 3D CAD modeling, the industry is evolving from traditional craftsmanship to data-driven design excellence.

So, what does the future hold for woodworking and millwork design? Let’s explore the major trends, challenges, and opportunities shaping the custom interiors of 2026 and beyond.

What Is Driving the Future of Architectural Woodworking and Design?

The shift toward innovation in architectural woodworking and design isn’t just aesthetic, it’s strategic. Businesses are turning to digital transformation and sustainability to stay competitive and meet modern client expectations.

Key drivers include:

- Digital Transformation: Firms increasingly use CAD and BIM software like AutoCAD, Revit, and SolidWorks for precision drafting and visualization.

- Sustainability Demands: Eco-friendly materials and energy-efficient processes are becoming standard.

- Customization at Scale: Clients expect bespoke interiors but want them delivered faster and at lower cost.

- Global Collaboration: Outsourced architectural millwork design services are helping UK and US firms meet tight project deadlines with consistent quality.

In essence, technology is empowering designers and builders to work smarter, not harder.

How Are CAD Tools Redefining Woodworking and Millwork Design?

The adoption of CAD-based millwork drafting has completely changed how professionals visualize and execute custom interior projects.

Precision Meets Productivity

Traditional woodworking relied heavily on manual drawings and physical prototypes. Today, CAD software eliminates errors by allowing millwork designers to create, test, and refine designs digitally before fabrication begins.

Benefits include:

- Error Reduction: Detailed 3D modeling ensures exact fits for joinery, cabinetry, and decorative elements.

- Cost Efficiency: Early detection of design conflicts saves time and material waste.

- Faster Turnaround: Automated drafting reduces project timelines significantly.

- Seamless Collaboration: Teams can share and review design data in real time, even across continents.

According to Autodesk’s 2025 design report, over 72% of architectural firms in the UK plan to increase investment in CAD and BIM tools to enhance millwork and interior design efficiency.

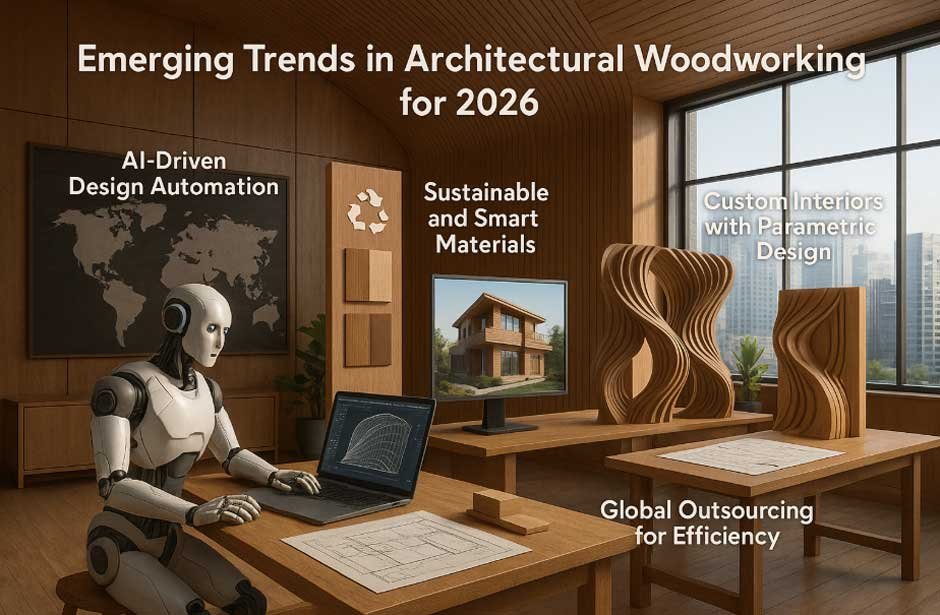

What Are the Emerging Trends in Architectural Woodworking for 2026?

The 2026 landscape of architectural woodworking and design will be shaped by innovation and sustainability. Below are the top trends experts predict will define the future of custom interiors:

1. AI-Driven Design Automation

Artificial Intelligence is now being integrated into architectural millwork drafting services to automate repetitive design tasks, optimize layouts, and suggest design improvements based on real-time data.

AI can predict material behavior, improve fabrication accuracy, and streamline approval workflows making it an indispensable tool for designers and engineers.

2. Sustainable and Smart Materials

Sustainability isn’t just a buzzword anymore. In 2026, clients demand environmentally responsible design. Expect increased use of reclaimed wood, bamboo composites, and low-VOC finishes.

In addition, smart materials capable of adjusting to temperature and humidity are entering the mainstream.

3. Digital Twin Integration

Digital twins, already popular in construction, are now transforming interior design. By creating an exact virtual replica of a space, designers can test how millwork elements fit, function, and age over time long before physical production begins.

4. Custom Interiors with Parametric Design

Parametric design allows designers to input parameters (like space dimensions or aesthetic rules) and let the software generate multiple design iterations. This enables faster experimentation while maintaining architectural accuracy.

5. Global Outsourcing for Efficiency

More UK and US firms are partnering with architectural millwork design companies in regions like India for CAD drafting and 3D modeling. This approach ensures cost savings, round-the-clock production cycles, and consistent quality control.

Why Custom Interiors Are Becoming a Competitive Advantage

In 2026, personalization is the new luxury. Businesses from hotels and retail brands to office spaces are investing in custom interiors that reflect their unique identity.

Here’s why custom millwork and woodworking design are becoming critical:

- Brand Identity: Bespoke interiors create memorable experiences and reflect corporate values.

- Functionality: Custom millwork improves spatial efficiency, especially in small or complex layouts.

- Durability: Precision design leads to long-lasting, easy-to-maintain installations.

A 2025 report by Statista revealed that nearly 68% of architectural clients in the UK now prefer custom-designed interiors over standardized solutions. This reinforces the growing value of craftsmanship paired with digital precision.

What Are the Biggest Challenges in Modern Millwork Design?

While opportunities abound, there are also key challenges designers must navigate:

- Skill Gap: Many traditional craftsmen are not yet fluent in digital tools like AutoCAD or Revit.

- High Software Costs: Advanced CAD systems require significant investment.

- Coordination Complexity: Large projects involving architects, engineers, and millwork designers demand seamless communication.

- Sustainability Pressures: Meeting green building standards requires continuous innovation in materials and methods.

Forward-thinking firms overcome these challenges by outsourcing specialized CAD tasks, upskilling their teams, and investing in collaborative cloud-based platforms.

How Will Technology Continue to Shape the Industry?

Looking ahead, the convergence of AI, AR/VR visualization, and robotic fabrication will redefine what’s possible in architectural woodworking.

Virtual and Augmented Reality

Designers can now immerse clients in 3D visualizations of their interiors using VR headsets making design reviews faster and more intuitive.

Robotic CNC Machining

Automation in fabrication ensures micron-level accuracy and reduces waste during cutting and shaping processes.

Cloud Collaboration

Cloud-based platforms allow real-time sharing of CAD files and millwork drawings, enabling hybrid teams across the UK, US, and Asia to collaborate seamlessly.

Together, these technologies promise a future where every design is smarter, faster, and more sustainable.

How Can Firms Prepare for the Future of Architectural Design?

To stay competitive, millwork and design firms should focus on:

- Investing in CAD and BIM training for designers and engineers.

- Adopting sustainable materials and eco-conscious fabrication practices.

- Leveraging global partnerships for CAD drafting and modeling.

- Integrating AI tools to automate drafting and error detection.

- Enhancing client experience with interactive 3D design presentations.

Firms that embrace innovation today will lead the market tomorrow.

Conclusion

The future of architectural woodworking and design lies in the harmony between craftsmanship and technology. As the industry moves toward automation, sustainability, and global collaboration, firms that blend creativity with digital precision will define the next era of custom interiors.

By leveraging tools like architectural millwork drafting services and 3D CAD modeling, design teams can deliver flawless, bespoke interiors faster and more cost-effectively than ever before.

For businesses seeking expert architectural millwork and design support in 2026, partnering with a leading UK CAD design company can bridge the gap between vision and execution turning concepts into stunning, build-ready realities.